Nos sites web pays

Nos autres sites web

Nos sites web pays

Nos autres sites web

Nos sites web pays

Nos autres sites web

Nos sites web pays

Nos autres sites web

Constructibilité

Constructibilité

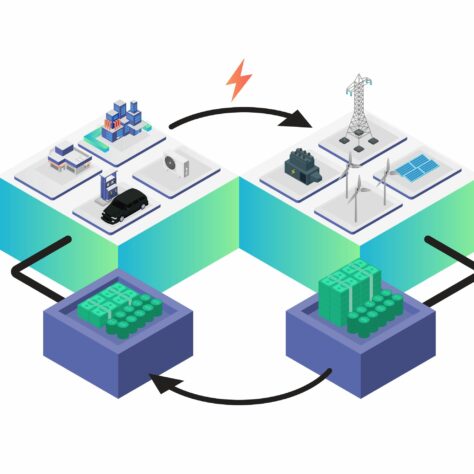

Transition énergétique

Transition énergétique

3S - Santé, sécurité et sûreté

3S - Santé, sécurité et sûreté

Planification des transports

Planification des transports